Grinding Process

“For three generations, we have been dedicated to offering our customers high-quality products by developing milling technology aimed at improving the performance of flours and their doughs.

Over time, we have gained significant expertise in both cylinder milling and stone grinding.”

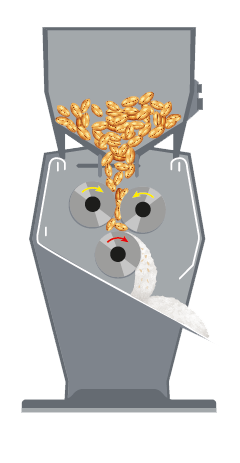

Cylinder grinding

Our historic cylinder mill, located at the headquarters, is dedicated to the milling of durum wheat and consists of a few rollers, minimizing the necessary steps for breaking the grain and reducing excessive stress on both the raw material and the flour.

Moreover, the elimination of the trimming phase from the classic milling process allows us to retain the germ, which is rich in vitamins (vitamin E and B vitamins) and essential fatty acids.

Therefore, our re-milled semolina is not only technologically suitable for various culinary preparations but also valuable from a nutritional standpoint.

ROLLING MILLS: rolling mills are metal boxes that contain 2 pairs of rollers, counter-rotating at different speeds and featuring distinctive grooves, so as to carry out distinct grinding steps;

OPTICAL SORTER: recognizes and discards seeds with a different colour from that of the wheat, thus perfecting the cleaning of the raw material.

AUTOMATIC PACKAGING MACHINE: ours is a modified atmosphere packaging machine (MAP – Modified Atmosphere Packaging) that allows us to extend the shelf-life of our flours, to maintain their organoleptic and nutritional characteristics.

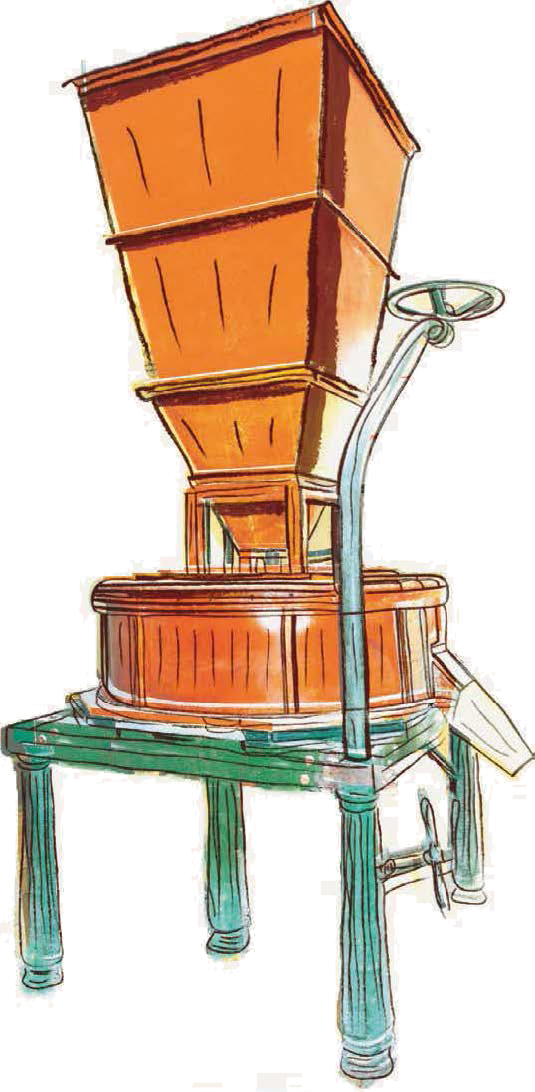

Stone grinding

The stone for our mills comes from La Ferté-sous-Jouarre, an ancient quarry near Paris from which, until the end of the 19th century, a particularly robust stone was extracted, suitable for resisting the mechanical stresses caused by the friction of grinding.

Our stone mills work at low temperatures, so as to preserve all the aromatic components typical of the raw material, sensitive to heat, and avoid the denaturation of proteins.

All this allows for obtaining more fragrant, tasty and nutritious flours, also thanks to the presence of wheat germ.

From stone grinding we obtain different types of flours, to satisfy any need of our customers!

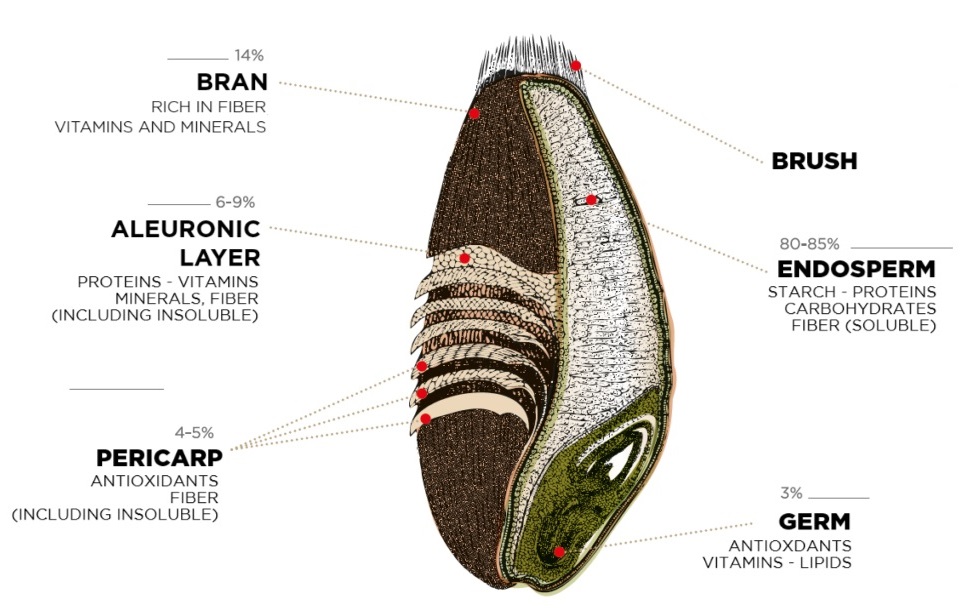

SOFT WHEAT FLOUR TYPE 1 or TUMBLED DURUM WHEAT FLOURS: they are deprived of the bran parts by successive passages in the sieve and, since they are more refined, they are commonly defined as “tumbled”. They have an almost uniform colour, light for soft wheat flours and ivory or amber for durum wheat flours, with a light speckling due to the presence of germ and bran (1-2%). They are ideal for preparing desserts, pizzas, bread and baked goods, both sweet and savoury.

TYPE 2 SOFT WHEAT FLOURS OR SEMI-INTEGRAL DURUM WHEAT FLOURS: they undergo less intense sifting than the tumbled product, therefore they have a higher bran content (4-6%). For this reason, the speckling is more accentuated and the flavour is also more intense.

The higher bran content reduces the leavening capacity of the doughs made with them, and they are therefore ideal for the preparation of slightly leavened desserts, focaccias, bread and baked goods, both sweet and savoury.

The higher bran content reduces the leavening capacity of the doughs made with

them, and they are therefore ideal for the preparation of slightly leavened desserts,

focaccias, bread and baked goods, both sweet and savoury.

WHOLE GRAIN FLOURS: these are the “true whole grains” because they are obtained by grinding grains entirely. Germ and bran blend with the flour, obtaining products with superior flavour and nutritional properties compared to the similar refined product.

Due to their resistance to leavening, they are ideal for bakery products, sweet or savoury, which require short leavening times.